Thermotech Engineering was incorporated in the year 1991 by two young technocrats, supported by a small but dedicated team of engineers, with an aim to serve the pharmaceutical, food/ beverage, personal care, chemical, petrochemical, and oil & gas industries.

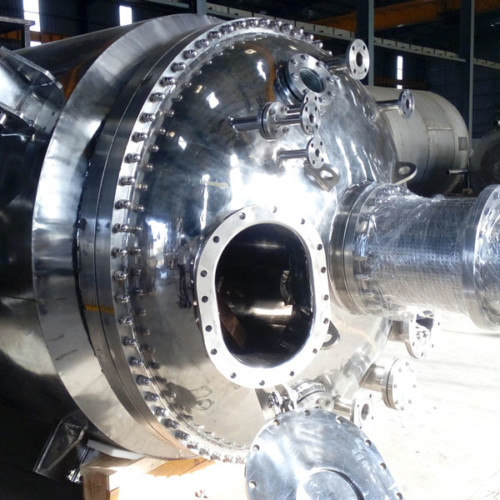

We design and manufacture cGMP and chemical reactors, agitators, pressure vessels, heat exchangers, and storage tanks

Starting from a small factory measuring 5,000 sq feet, and a few people, today thermotech has two state of the art manufacturing facilities spread over 4 acres. One factory is in the thriving industrial township of Chinchwad, admeasuring one acre. The second is in the Chakan industrial area (near Pune) admeasuring three acres.

Today we have a team of 150 people, and produce nearly 250 reactors per annum

Plant and Machinery

Thermotech has two factories of with factory area of 44,000 sq. feet, 6000 sq. feet each. All factories have overhead cranes, concrete tremix flooring.

Our most recent factory at Chakan has an open yard area of 50,000 sq. feet, and a covered factory area of 50,000. The covered workshop area has a roof height of 11 mtrs, and EOT cranes of 20 Tonnes.

Engineering / Design

Thermotech has 28 years of experience in designing mixers for various applications. Whether the material is complex, or a reaction critical, we have likely dealt with it in the past, and can bring our experience to your benefit.

We have mechanical engineering expertise for the design, independent design verification, analysis, re-rating, fitness for service assessments, and fabrication specifications of pressure vessels. High standards are maintained and supported by an ISO 9001:2000 (TUV Austria) certified quality system.

Quality Control Systems

Thermotech has robust quality systems that ensure that the right material is used, and the right procedure is followed in the conversion of raw material to finished product. We have a dedicated Quality manager, and a team of 9 field engineers ensuring strict compliance with procedure, and adherence to QAP

Thermotech and quality are synonymous. We take great care at every stage of the manufacturing process, from material procurement, till painting and dispatch. All the incoming material is first tested by PMI, all shafts are ultrasonically tested. The best quality of filler wire is used to ensure strong and proper welds. Polishing and buffing are done with abrasive media which are free from Iron content. Roughness is measured by state of the art Mitutoyo Ra Meter.