INTRODUCING DYNAMIC ENGINEERING

Dynamic engineering company is in Electromagnetic Vibrating systems for industries. We market, VAIDEHI brand of Vibrators, Feeders and Bowl Feeders (Component Feeder).

We offer made to order low cost automation feeders to industry since 1982. With experience, we now tool feeders for almost TEN new components every month for specific orientation.

By using latest technologies, best available raw material, we can guarantee fast and efficient supply of accessories for entire range of product and service them within any geographical area.

Know Ourselfs

Dynamic Engineering Company deals in VAIDEHI Brand of Electromagnetic equipments for low cost automation to the industry. We are offering our services since 1982. to packaging machinery manufacturers, electronic and electrical component assembly, testing, inspection production line manufacturers, bulb and medical equipment production line manufacturer, automobile and related component production line manufacturers.

Our Products

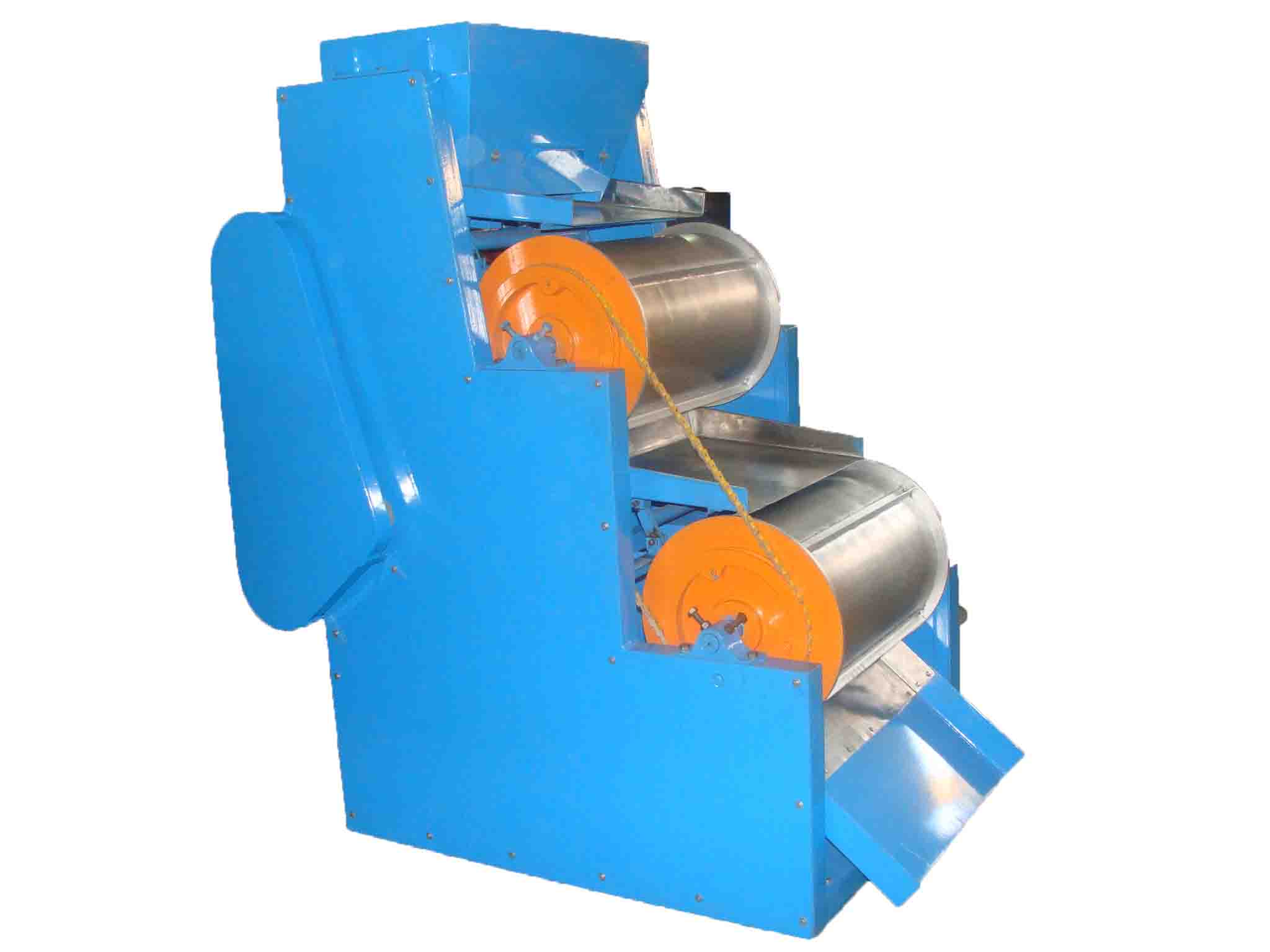

Rare Earth Magnetic Coolant Filters

AIDEHI Rare Earth Magnetic Coolant Filters are latest development with the use of super power rare earth magnets that is almost 8 times higher in force than that of conventional ferrite magnets. These filters are most efficient due to its magnetic force, smaller in size with better filteration level. By using FHP Motor and gear head it is very energy efficiet too.

These Magnetic coolant filters are available in the range of 50 Ltrs. to 400 Ltrs. per minutes filtering capacities.

Higher Capacities, available on request.

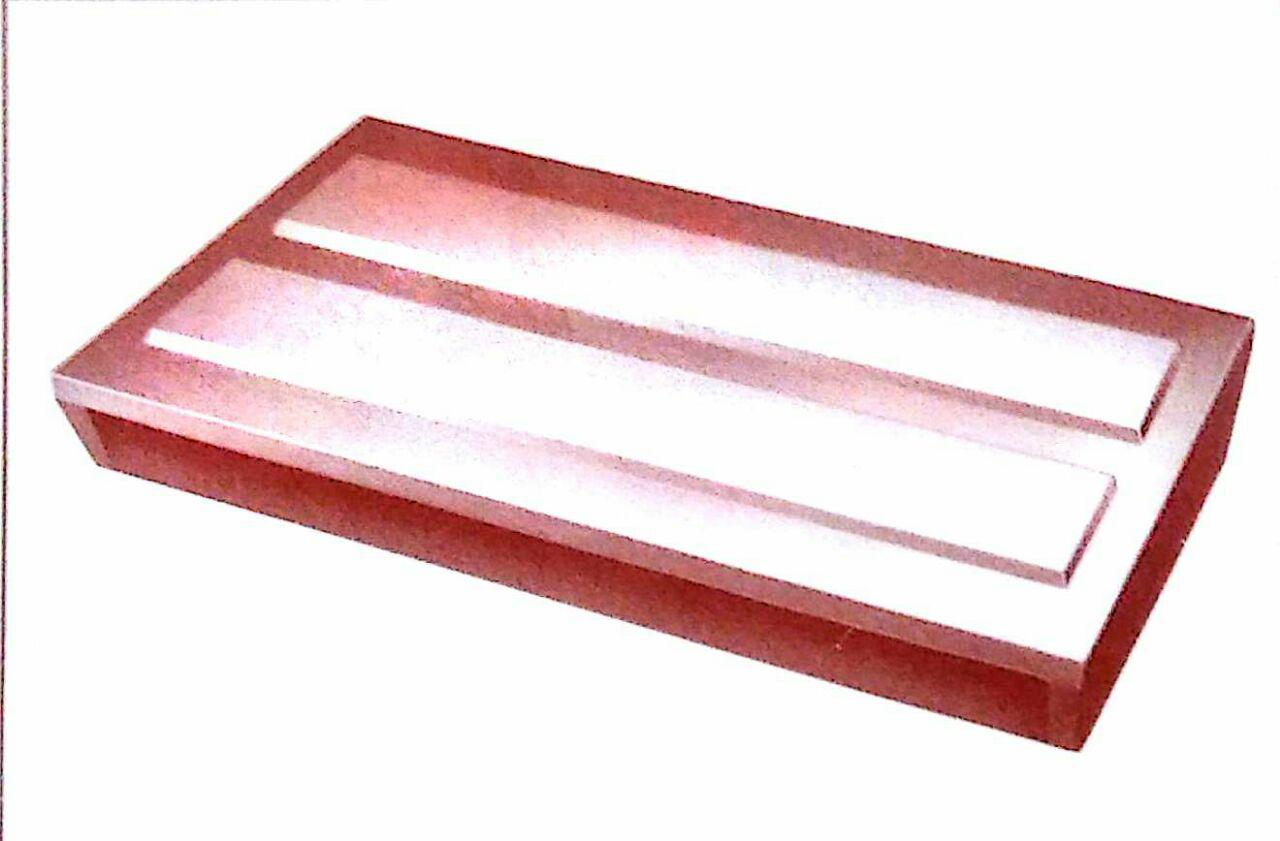

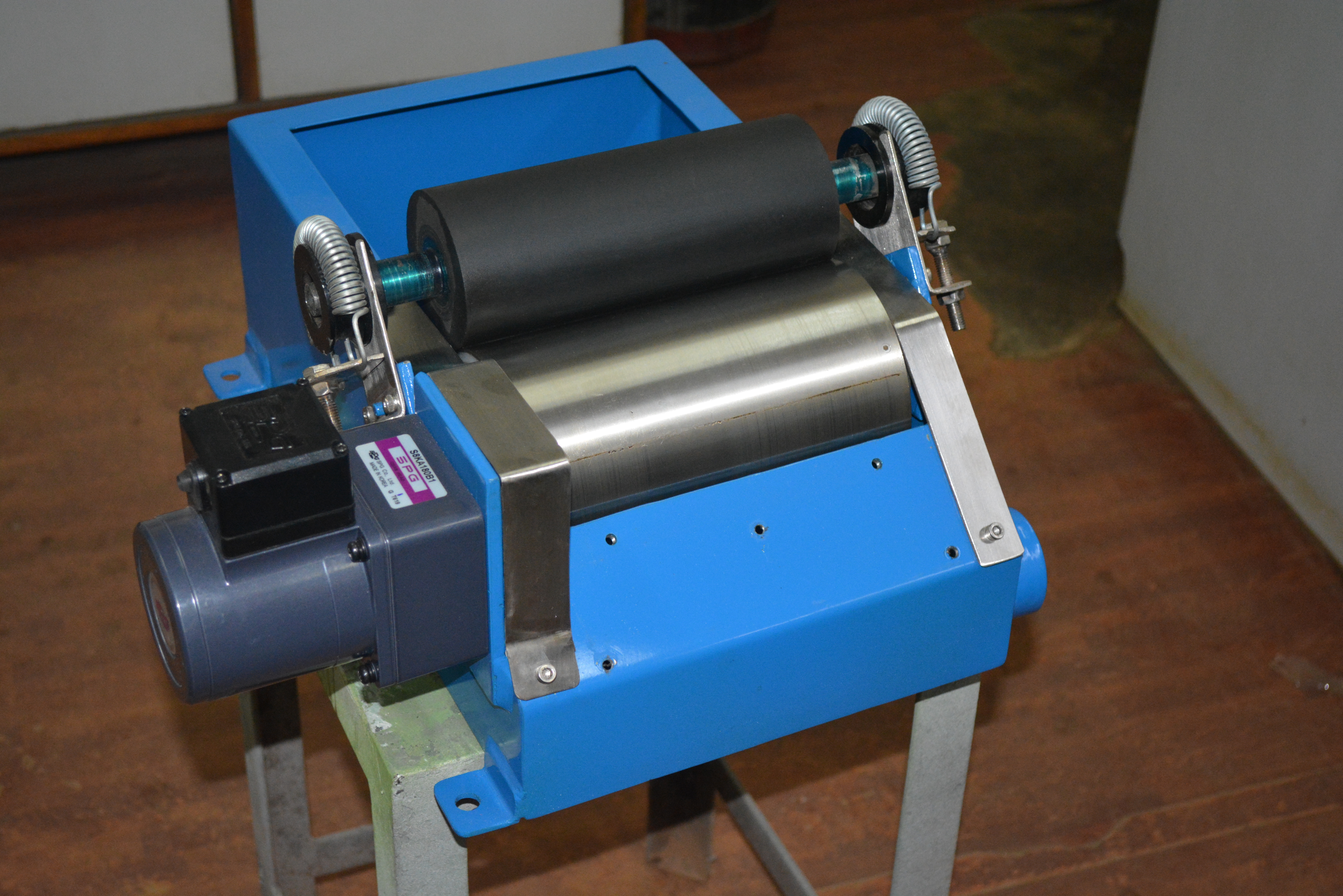

Magnetic Coolant Filters

VAIDEHI Magnetic Coolant Filters are designed for filtering coolant oil contaminated with ferrous materials. The contaminated coolant from the machine is fed into the inlet of Magnetic filter, which passes through the gap between the magnetic drum and the body , the drum is driven by a double reduction worm geared motor, the dust particles are attracted and held firmly by the magnetic drum. A synthetic rubber roller mounted on springs squeezes the dust and allows only dry dust ,which is scraped out from the drum by scraper and collected separately in the dust collecting tray.

The filteration level achieved is almost 80% for ferrous particles. These magnetic coolant filters are available in the range 50 Ltrs. To 1000 Ltrs. per minutes filtering capacities.

Higher capacities, available on request.

Drum Type Paper Filter(Compact Design)

VAIDEHI compact band filter is designed to filter contaminated coolant/cutting oil with high degree of purification using paper as filter media to enchance life of coolant and improve the surface finish of the product. Now a days the shop floor area is a major constraint. Drum Type paper Filter is so designed that it is possible to reduce the floor area substantailly when compared to conventional flat type paper band filter. The system is normally mountable to the existing tank available.

It is further possible to use different grade of filter paper to achieve various grade of filtration. The system is completely automatic and also the filter paper is sealed on all sides so as to eliminate any contamination of the coolant.

The system does not require any manual attention.

Paper Band Filter

VAIDEHI Paper band cum magnetic coolant filters are designed for filtering ferrous and non-ferrous particles with high degree of purification. The contaminated coolant from the machine is first passed through the magnetic filters where almost 95% of the ferrous particles are separated.

The coolant further passes through the paper filter where all non-ferrous particles are filtered. When filter paper is clogged, it raises the coolant level and actuates the float switch to bring fresh paper from the paper roll. Clean coolant is collected in the bottom tank for re-circulation to the machine.

The unit consists of tank, pump, chain conveyor, geared motor, control panel with suitable magnetic coolant clarifier.

Contact Us

Address: D-7/3, Okhla Industrial Area, Phase-II, Delhi 110020

Phone: +91-11-41406222

.jpg)