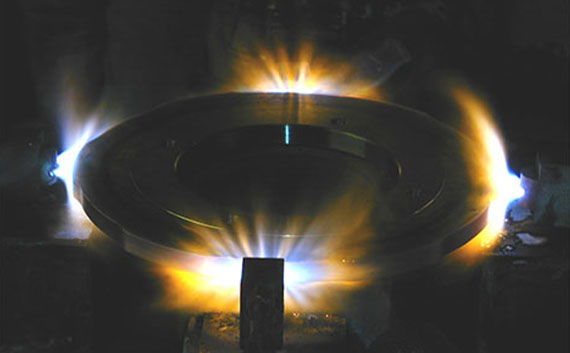

GRIFLAM® flame hardening technology – our made to measure solution for case hardening of your components. Through our individually manufactured GRIFLAM® flame hardening torches, heat can be introduced targeted to the case layers of the part. By quenching with water or compressed air the hardness can thus be increased in a targeted way and the surface protected against abrasion.

Flame Hardening is usually be done by torches suitable for acetylene in combination with oxygen. Furthermore, torches for slow burning gases like propane, methane or MAPP in combination with oxygen are common. Beside standard torches, also torches with adapted shapes fitting to the work pieces are applicable. Moreover, torches with built-in quenching shower heads can be designed as well.

The process is suitable for quenchable iron materials as well as for construction and tempering steels with at least 0.3% C content. The hardness can be influenced directly depending upon the feed speed or hardening time and distance to the water or compressed air nozzle.

|

Messer Cutting India

All Rights Reserved. |