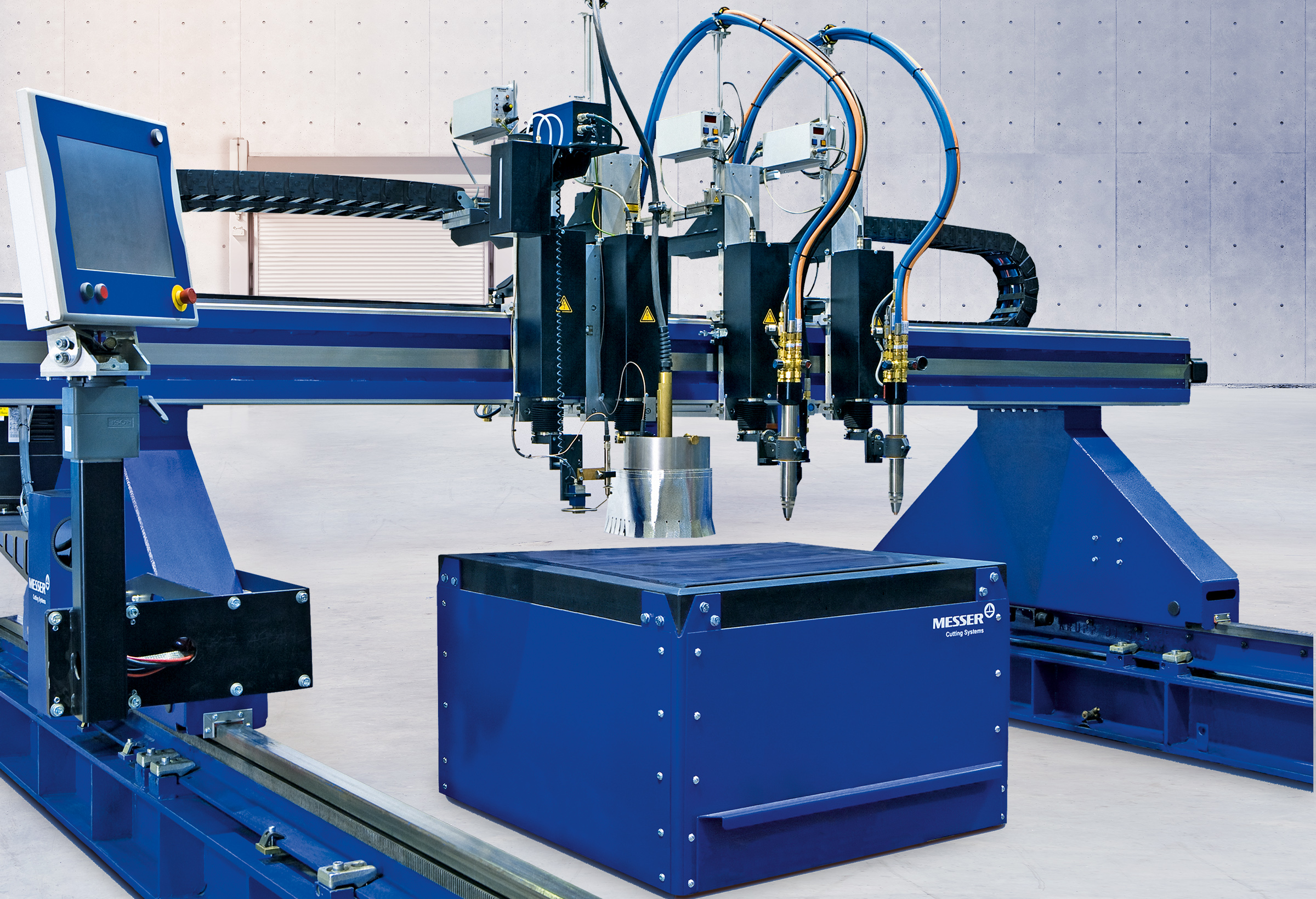

Do you need a compact machine which is flexible and easy to use for your daily work? The MultiTherm® Eco is the perfect universal machine for oxyfuel and plasma cutting. Efficient cutting productivity due to a high level of automation and easy set-up and operation produces quality components - quickly and efficiently.

YOUR ADVANTAGES

(1) Conditions apply

The user-friendly CNC control Global Control speeds set-up and reduces errors and non-productive times.The intelligent torch lifter SL200 for plasma allows time-saving cycles and high stroke speeds. Multiple ALFA torches with quick nozzle change permit high productivity.

The symmetric wheel-housings and parking space for temporarily unused heads optimise the working width but keep space requirements reasonable. The combination of oxyfuel and plasma cutting processes cover all commonly occurring materials and tasks. The MultiTherm® Eco impresses with high dynamic and is suitable for bevel cutting.

|

Messer Cutting India

All Rights Reserved. |