Our low overheads help provide you with cost benefits while maintaining the superior technical effectiveness of a company of 20 years of experience. We have the capability to enhance your efficiency by providing resources like Man, Machine, software or combination of all at your facility.

7 Reasons Why You Should Consider Opptum as Your Mold Flow Analysis Partner….

1. We are associated with Tool and Mold Industry since the last two decades.

2. Opptum is one of the fastest growing startup company in Pune in this industry, Our low overheads help provide you with cost benefits while maintaining the superior technical effectiveness of a company of 20 years of experience.

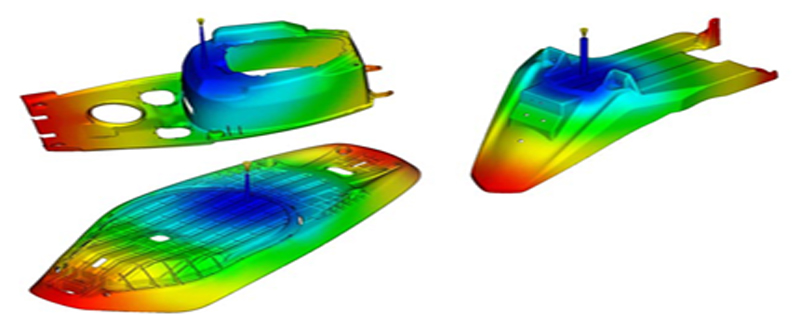

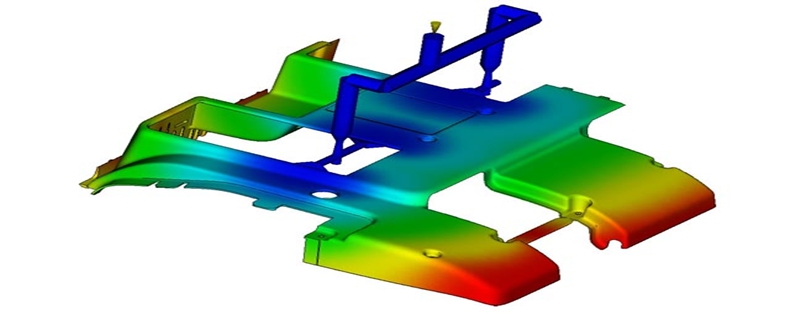

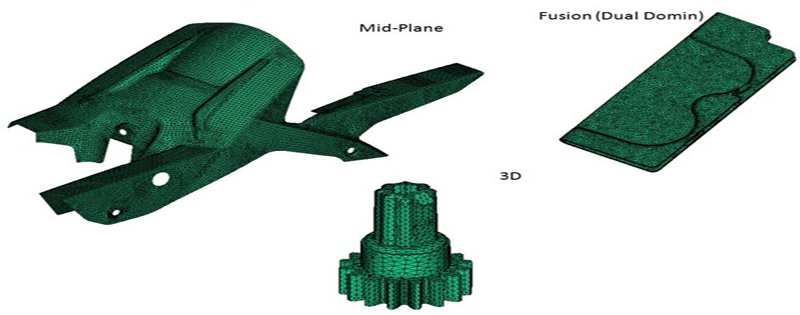

3. Using the latest authentic Autodesk Moldflow Insight 2016 software we have analysed over 1000+ components across industry domains.

4. We specialize in Automotive, FMCG, Medical & the Electronics industries.

5. We have a highly experienced Engineering team of trained Moldflow Analysis Engineers.

6. We help optimize design solutions with good tooling, part design & molding expertise. we have Proven experience with all major OEM, Tier 1 & Tool Makers.

7. Our strength is to deliver the moldflow analysis report to you within Three working days, for small and medium size components with high quality standards.

Advantages for our Customers

- Improved product quality.

- Reduction of development time.

- Reduced efforts during molding trials.

- Optimized manufacturing processes.

- Better understanding of the complex rheological and thermal phenomena during molding.

- Cost savings. Increase of customer satisfaction.

Benefit of MoldFlow Simulation

- Efficient Process Conditions.

- Optimum Cooling for Cycle Time Savings.

- Optimum Gate Position for Minimum Machine Size.

- Position Weld Line Where You Want Them. Runner Balancing for Minimum Scrap.

- Eliminate Air Traps, Sink Marks & Burning. Minimize Clamp Force Requirements.

- Control Fiber Orientation.

- Even Part Shrinkage. Gas Injection Simulation.

- Reduced Warpage at Fast Cycles.

Area of Expertise

1. Identifying the most suitable material.

2. Optimizes the part's wall thicknesses to achieve a uniform filling.

3. Determines the optimal gate location for the part.

4. Identifies and eliminates aesthetic defects such as sink marks, weld lines and air vents.

5. Achieving optimal weld line placement.

6. Arriving at correct tool layout and runner designs required.

7. Providing complete report which eliminates expensive process of trial & error.

8. Allows achieving quality injection molded parts at very first time

WHY CHOOSE US

ADVANCED TECHNOLOGY

Using the latest Autodesk Moldflow Insight 2018 software we have analysed over 1000+ components across industry domains.

DELIVERY ON TIME

Our strength is to deliver the Moldflow Analysis report to you within three working days, for small and medium size components with high quality standards.

EXPERIENCED ENGINEERS

We have a highly experienced & trained combination of Mechanical, Polymer, NTTF and GT&TC Graduate Engineers with hunger to grow attitude.

EXPERIENCE OF OVER 2 DECADES

We are proud to say that we have offer series of solutions for design optimization, parts design & molding. Therefore we are first choice major OEM, Tier 1 & Tool Makers.

SPECIALISED FOR INDUSTRIES

We specialize in Automotive, FMCG, Medical & the Electronics industries.

COST OPTIMISED SERVICES

Due to our low overheads we could offer cost effective solutions, not only matches, exceed the superior technical effectiveness of the players of 2 decade experience.