Ultramax Vapor Degreasing is an economical way to clean in the manufacturing process as the solvents are reused. Today’s demanding product performance often requires components machined or stamped to very tight specifications. Current industrial standard requires Lubricants, dust, metal particulate, fingerprints or other residues must be removed prior to processing or assembly. . This process needs to safely displace common soils — machining oils, stamping oils, cooling oils, metal fines, marking inks, greases, fingerprints and/or waxes — without damaging substrates ex. Medical implants cleaning. This is simple solvent based parts washer or degreasing equipment generally used in precision cleaning application.

Process

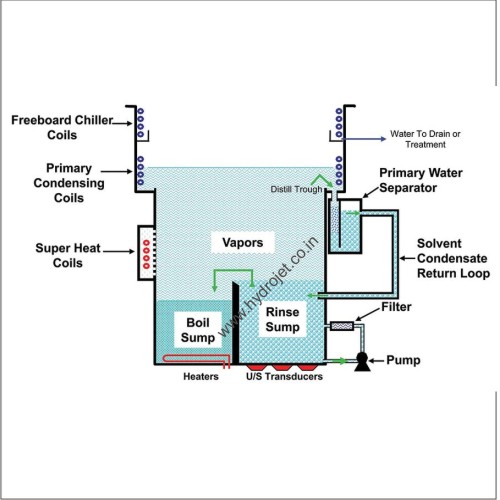

Our industrial cleaning machine are simplest form of degreaser boils a solvent into vapors and fumes. Because warm vapors are lighter (less dense) they rise upwards in the machine but are trapped by a layer of refrigeration which creates a temperature inversion. The vapors then condense back into liquid form and returned in to the cleaning machine. Important point to understand, and unlike water based cleaning the solvent never loses its property. Because the solvent is constantly being purified and recycled, it is used hundreds or even thousands of times. This makes vapor degreasing very, very affordable.

Accessories

- Wash chamber

- Heater

- Component basket

- Condensing coil

- Ultrasonic generator