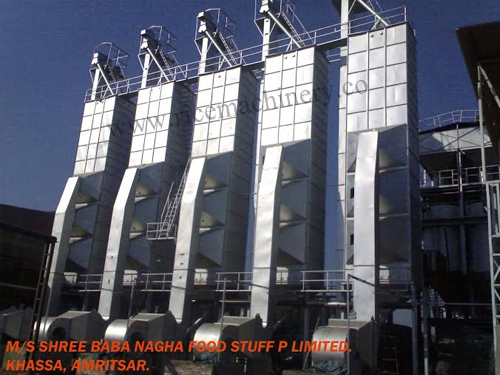

We manufacture paddy dryer of Husk furnace with two pass special alloy M.S. tube air pre heater. The flue gas in this heater passed through multiple pass., air to air exchanger made of (M.S. Tube just like in case of steam heat exchanger.)

The Paddy in the dryer is dried by hot air. The hot air is prepared by our special pre heater on husk furnace does not require boiler is not required only when dryer is installed. Boiler is required only for boiling on paddy.

DESIGN FEARURES

Elevator : Heavy duty two way bucket elevator specially designed for continuous duty.

Biins : Designed for maximum stroage and smooth out flow.

Dryer : Based on sphisticated American technology for optimum yield and best quality.

Furnace : Efficient Husk fired furnace with regulated air flow resulting maximum thermal efficiency.

SIZES OF DRIER PLANT

| S. NO | DRIER CAPACITY 65 KG. PER PAG | DRYING. CAP. 24 HOURS (RAW) | SELA 24 HOURES | REQUIRED H.P. | SPACE |

| 1. | 8 Tone 125 bags | 2 batch | 1.5 batch | 22 HP | 15' * 35' |

| 2. | 12 Tone 175 | 2 batch | 1.5 batch | 27 HP | 15' * 35' |

| 3. | 16 Tone 250 | 2 batch | 1.5 batch | 32.5 HP | 15' * 35' |

| 4. | 20 Tone 300 | 2 batch | 1.5 batch | 40.5 HP | 15' * 35' |

SALIENT FEATURES

1. Optimum yield, 2. Minimum rice breakage, 3. More percentage of oil in bran, 4. Minimum Maintenace, 5. Minimum capital investment, 6. Minimum labour requirement, 7. Simple in Operation, 8. Small land required, Minimum requirement of Husk

|

G. S. Agro Systems

All Rights Reserved. |